Call us now : 07971584680

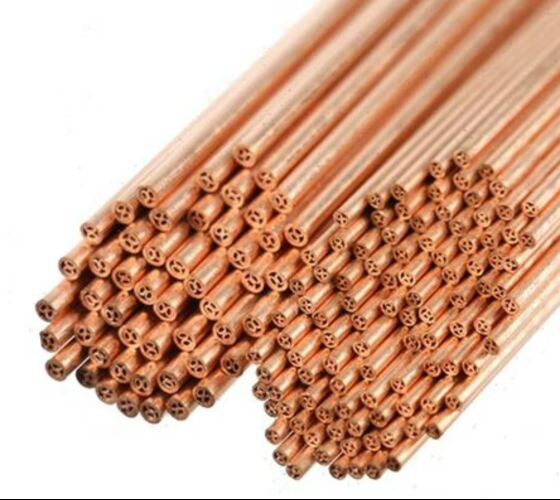

Multi hole copper electrodes tube

30 INR/Number

Product Details:

X

Multi hole copper electrodes tube Price And Quantity

- 1 Number

- 30 INR/Number

- 30.00 - 100.00 INR/Number

Multi hole copper electrodes tube Trade Information

- Cash in Advance (CID)

- 1000 Number Per Day

- 2 Days

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

Multi-hole copper electrodes are specialized electrodes used in Electrical Discharge Machining (EDM), particularly in Sinker EDM (also known as Plunge EDM) and sometimes in Wire EDM applications. These electrodes are typically made of copper due to its excellent electrical conductivity, machinability, and high thermal conductivity, which is crucial for the EDM process.

Key Features of Multi-Hole Copper Electrodes:

-

Design with Multiple Holes:

- These electrodes have multiple drilled holes through the body of the electrode. These holes are carefully positioned and drilled to achieve specific cooling or flushing patterns.

- The primary purpose of the holes is to allow for better dielectric fluid circulation during the EDM process. The dielectric fluid (typically oil or deionized water) flushes away debris and provides cooling to both the electrode and the workpiece.

-

Improved Cooling and Efficiency:

- The multiple holes allow for efficient cooling as the dielectric fluid flows through the holes, directly impacting the heat-affected zone. This cooling helps to maintain stable cutting conditions and prevent overheating of the electrode and workpiece.

- Better flushing of the debris generated by the electrical discharge, helping to maintain cutting accuracy and prevent clogging or erosion of the electrode.

-

Precision and Fine Detailing:

- Multi-hole copper electrodes are often used for high-precision machining when creating intricate parts or shapes. The design of the electrode allows for more controlled material removal and better flushing of the machining zone.

- The holes also contribute to more uniform wear across the electrode surface, which is important for maintaining consistency in the EDM process.

-

Electrode Longevity:

- Copper is a material chosen for its resistance to wear and high thermal conductivity, allowing the electrode to last longer during the EDM process compared to other materials like graphite or copper-tungsten.

- The multi-hole design enhances the overall efficiency and longevity of the electrode by ensuring that the electrode is evenly cooled and less prone to premature wear or failure.

Applications of Multi-Hole Copper Electrodes:

-

Sinker EDM: In this type of EDM process, the electrode is used to create precise shapes and cavities in the workpiece. The multi-hole copper electrodes are crucial for providing cooling and flushing in deep cavities or complex geometries where a regular electrode might struggle with heat buildup and debris removal.

-

Precision Parts Manufacturing: Multi-hole copper electrodes are often used in the production of precision molds, dies, and tools where the highest level of accuracy and surface finish is required.

-

Complex Cavities: These electrodes are ideal for deep-hole drilling, blind holes, and other complex features in parts where uniformity and consistency are critical.

Advantages of Multi-Hole Copper Electrodes:

- Enhanced Cooling: The multiple holes provide an efficient way to cool both the electrode and the workpiece during the machining process, preventing overheating and thermal damage.

- Improved Material Removal: The holes also improve the flushing of the dielectric fluid, which helps in removing debris generated during the discharge process, resulting in cleaner and more precise cuts.

- Uniform Wear: The design allows for more even wear on the electrode, increasing its lifespan and reducing the need for frequent replacements or adjustments.

- Customization: Electrodes can be designed with different hole patterns, sizes, and orientations based on specific machining requirements, offering versatility for different types of cuts.

Conclusion:

Multi-hole copper electrodes are a critical tool in EDM machining, especially for applications requiring high precision and efficient cooling. The multiple holes in the electrode body allow for better dielectric fluid circulation, improved flushing, and more uniform wear, all of which contribute to a more efficient and durable machining process. These electrodes are especially valuable in industries like aerospace, automotive, and precision tool manufacturing where intricate details and smooth finishes are essential.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free