Call us now : 07971584680

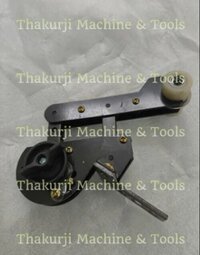

Wire Tightener

6000 INR/Number

Product Details:

X

Wire Tightener Price And Quantity

- 1 Number

- 6000 INR/Number

- 2000.00 - 6000.00 INR/Number

Wire Tightener Trade Information

- Cash in Advance (CID)

- 10 Number Per Week

- 2 Days

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

An EDM Wire Tightener is a crucial component used in Wire Electrical Discharge Machining (Wire EDM), a process where a thin wire (usually made of brass or copper) is used as an electrode to cut through electrically conductive materials. The EDM wire tightener is used to maintain precise tension on the wire throughout the machining process to ensure accurate cutting and high-quality results.

Key Features of an EDM Wire Tightener:

-

Wire Tension Control:

- The primary function of a wire tightener is to maintain consistent wire tension during the EDM process. Proper wire tension ensures that the wire remains straight and does not sag or deflect, which could lead to inaccurate cuts and poor surface finishes.

- The tightener adjusts the wire tension, providing a balance between the wire's flexibility and the required precision for cutting the workpiece.

-

Accurate Cutting:

- In Wire EDM, the thin wire is used to erode the material by means of electrical discharges. If the wire tension is inconsistent, it can lead to misalignment and poor cutting quality. The tightener ensures that the wire maintains a constant tension, which is crucial for precise, smooth cuts.

- A uniform wire tension helps in maintaining accurate positioning of the wire relative to the workpiece, reducing the risk of wire wander or deflection during operation.

-

Automatic or Manual Adjustment:

- Automatic EDM wire tighteners are controlled by the machine™s CNC (Computer Numerical Control) system. These systems automatically adjust the wire tension as required during the machining process to account for changes in wire diameter, wear, or thermal effects.

- Manual wire tighteners, on the other hand, require operators to adjust the tension by hand. This type may be used in machines where CNC control of the wire tension is not available or in simpler EDM setups.

-

Wire Wear Compensation:

- As the wire erodes during the EDM process, its diameter gradually decreases. Wire tighteners with automatic tensioning systems can compensate for the decrease in wire diameter, maintaining a constant tension. This is particularly important in longer jobs or deep cuts, where wire wear could otherwise affect precision.

-

Durability and Stability:

- The EDM wire tightener is designed to operate in high-temperature environments due to the heat generated during the electrical discharge. It is usually made of durable materials such as steel, and it can withstand the mechanical and thermal stresses encountered during EDM machining.

How EDM Wire Tighteners Work:

-

Mounting and Positioning:

- The wire tightener is typically mounted on the wire feed system of the EDM machine. The wire passes through the tightener, which is positioned either at the upper or lower part of the machine to apply tension evenly across the length of the wire.

-

Tension Adjustment:

- The wire tightener uses a spring or hydraulic system to adjust the tension of the wire. In some systems, the tightener is integrated with a force sensor that monitors the wire tension and adjusts it automatically.

-

Maintenance of Tension:

- During the cutting process, as the wire gets used up and wears down, the tightener automatically compensates for the loss in wire diameter by increasing tension to keep the wire taut. This ensures that the wire always remains in proper contact with the workpiece, allowing for consistent cutting performance.

-

Monitoring and Feedback:

- Some modern EDM machines with wire tighteners provide feedback mechanisms that alert the operator to any changes in wire tension or irregularities in cutting. This allows the operator to adjust settings if necessary, ensuring high-quality and accurate machining.

Types of EDM Wire Tighteners:

-

Spring-Based Tightener:

- The simplest type, where a spring is used to apply a constant tension to the wire. This type may be manually adjusted to change the tension as needed.

-

Hydraulic Tightener:

- Uses hydraulic pressure to apply tension, providing precise and consistent control. This type of tightener is often more durable and reliable, making it suitable for larger and more demanding EDM applications.

-

Pneumatic Tightener:

- Operates using compressed air to control the wire tension. Pneumatic wire tighteners are often used in automated systems where quick adjustments are required.

-

CNC-Integrated Tightener:

- In modern EDM systems, wire tighteners are often integrated with the CNC control system. These tighteners can automatically adjust tension during the machining process based on real-time feedback from the machine.

-

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free