Call us now : 07971584680

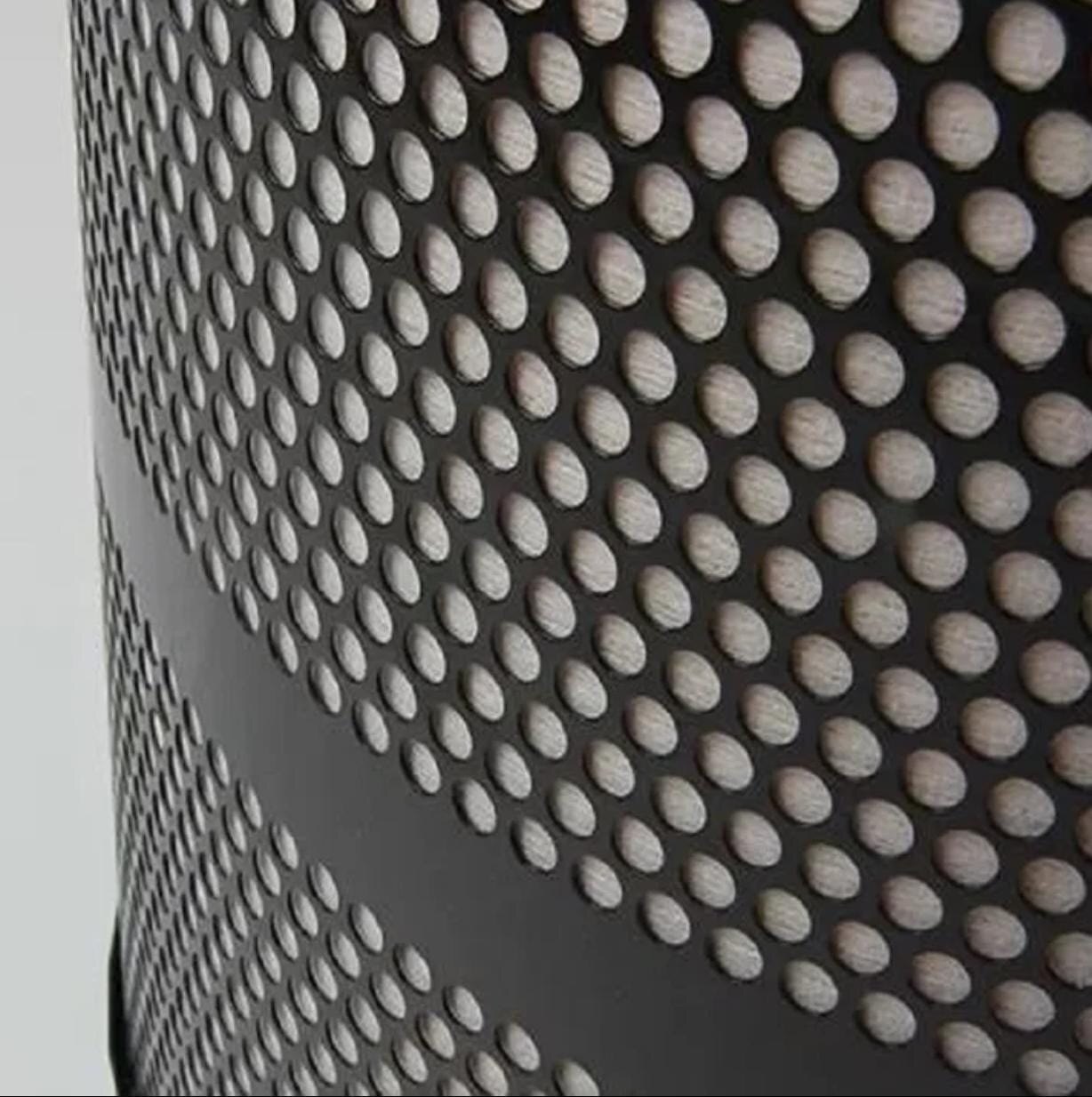

SODICK WIRE CUT FILTER

7000.0 INR/Number

Product Details:

X

SODICK WIRE CUT FILTER Price And Quantity

- 7000.00 - 8000.00 INR/Number

- 7000.0 INR/Number

- 2 Number

SODICK WIRE CUT FILTER Trade Information

- C A ) ' , ' C a s h i n A d v a e D ) ' A d v a n c n ] [ ' C a s h e ( c ( C I

- 7 Days

- Yes

- e p b y s h i p p i n d t a x e s h a s t a i d t h e b [ ' S a n g a o b ' ] m p l e c o s t s u y e r

- ' A u s t r a ' C e r i c a ' , ' N o r t h A m e r i c a ' , ' S o u t m e ' h A r i c a ' W e s t e r [ ' A s i a ' , l i ' , a l e ' , ' M t ' , a n t r A m n o p e ' E u s E a s t e r E u r , r n o p e ' , i d d l e E a ' A f r i c a ' ]

- n d , ' k s , i z m ' r a P B i h ' C a n d D i u ' k a , ' ' D a d a d v e l i ' , d I s a n d ' n a c h P n a m m a , , a l d i a ' ' s t I n d i , ' n d i , I i [ ' l I n ' S h n i a ' i a ' , o n t r , W e o r t h I a ' E a ' , ' s h ' U t t a r a k h a n d ' , A l d u t a ' N d w e e p ' M o r a ' , M e g h a l a y a ' i p u r ' ' A n a d s h ' , a n d i g a r h ' , ' D a m a n , a r ' s h j a b ' , ' A s s a m r H a n a n d N i c o I d ' C e I n ' s t a G u j a t , t a k a ' , ' r a a h a , ' M a n , d h r e ' ' , h h n d ' , O a ' , ' P u n ' N ' A n a m a , ' A u r a s h m i r ' M a d r a s t r a ' r a ' ' K a r n a K e l L a ' a r ' G o ' , ' J h a d i D e l h i ' , r a n a g a a l a d e h C h h g a r h ' , ' H a r y a e s h ' , ' J u n d K a , , ' S i k T a m i l n ' T r i ' U t t a b a r l s r s ' , ' a t t i s ' , ' H i m a c h a l P r a d ' h y a P r a d e s h ' ' M a h a h ' a g a l a n d ' , ' R a j a n N a d u ' , ' T e l a g a n a ' , p u r a ' , ' P o n d i c h e r r y ' , r P ' , N a s t h ' k i m ' , ' r a d e ' , ' W e s t B e n g a l ' ]

Product Description

Sodick is a renowned manufacturer of EDM machines, including wire-cut EDM.

To ensure optimal performance and longevity of these machines, they offer a range of specialized filters.

www.sodick.co.jp

2. FiltersSodick

www.sodick.co.jp

Types of Sodick Wire Cut Filters

While specific details might vary based on the exact model of your Sodick wire-cut EDM machine, generally, these filters can be categorized into:

- Water Filters: These filters purify the water used in the EDM process, removing impurities that can affect cutting accuracy and electrode life.

- Oil Filters: Employed in specific EDM systems, these filters clean the oil used in the dielectric fluid, preventing contamination and maintaining machine efficiency.

Key Functions of Wire Cut Filters

- Impurity Removal: Filters capture and retain particles, sludge, and other contaminants from the dielectric fluid.

www.ctemag.com - Fluid Life Extension: By removing impurities, filters help extend the lifespan of the dielectric fluid, reducing replacement costs.

- Machine Protection: Clean dielectric fluid helps prevent damage to sensitive machine components.

- Cutting Quality Enhancement: Clean fluid contributes to better cutting accuracy, surface finish, and overall part quality.

Sodick Filter Features and Benefits

- High Efficiency: Sodick filters are designed to capture even fine particles, ensuring maximum fluid cleanliness.

- Durability: Built to withstand the harsh environment of EDM operations, these filters offer long service life.

www.taguti.net - Compatibility: Sodick filters are specifically designed for their EDM machines, guaranteeing optimal performance.

- Cost-Effective: By extending fluid life and preventing machine issues, Sodick filters can help reduce overall operating costs.

Additional Considerations

- Regular Maintenance: Consistent filter inspection and replacement are crucial for maintaining machine performance.

- Filter Selection: Choosing the correct filter type and micron rating is essential for your specific application.

- Filter Disposal: Proper disposal of used filters is important for environmental protection.

Note: For precise information about the specific filters required for your Sodick wire-cut EDM machine, it's recommended to consult the machine's user manual or contact Sodick directly.

Understanding the Importance of Wire Cut Filters

Q: Why is a filter crucial for a Sodick wire cut machine?

A: The filter plays a vital role in maintaining the cleanliness of the dielectric fluid. Contaminants like metal particles, sludge, and other impurities can affect the cutting accuracy, surface finish, and overall machine performance. A clean filter ensures optimal cutting conditions.

Q: What are the signs of a clogged filter?

A: Common signs include:

- Increased cutting time

- Rougher surface finish

- Frequent wire breaks

- Reduced dielectric flow

- Unusual noises from the machine

Filter Selection and Maintenance

Q: How do I choose the right filter for my Sodick machine?

A: The filter should match the specific model of your Sodick wire cut machine. It's essential to check the filter's specifications, including micron rating, flow rate, and dimensions. Consult the machine's manual or contact the manufacturer for guidance.

Q: How often should I change the filter?

A: The filter replacement frequency depends on several factors, including:

- Workpiece material

- Cutting conditions

- Dielectric fluid type

- Filter efficiency

Generally, it's recommended to inspect the filter regularly and replace it when it becomes visibly dirty or clogged.

Q: Can I clean and reuse the filter?

A: While some filters can be cleaned, it's generally not recommended. Reusing a filter may compromise its efficiency and lead to premature clogging. It's safer and more reliable to replace the filter with a new one.

Filter and Machine Performance

Q: How does filter quality affect cutting performance?

A: A high-quality filter with a fine micron rating effectively removes contaminants, leading to:

- Improved cutting accuracy

- Better surface finish

- Longer wire life

- Reduced downtime

Q: Can a clogged filter damage the wire cut machine?

A: Yes, a clogged filter can restrict dielectric flow, causing overheating and damage to the machine components. It's essential to maintain a clean filter to protect your investment.

Additional Tips

Q: Are there any preventive measures to prolong filter life?

A: Regular dielectric fluid maintenance, using high-quality fluids, and avoiding excessive contamination can help extend filter life.

Q: Can I use a different brand of filter for my Sodick machine?

A: While it might be possible, using a filter specifically designed for your Sodick machine is recommended to ensure optimal performance and compatibility.

Q: What should I do if I experience filter-related issues?

A: If you encounter problems with your wire cut filter, contact the Sodick service center or a qualified technician for assistance. They can diagnose the issue and provide appropriate solutions.

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry Send SMS

Send SMS