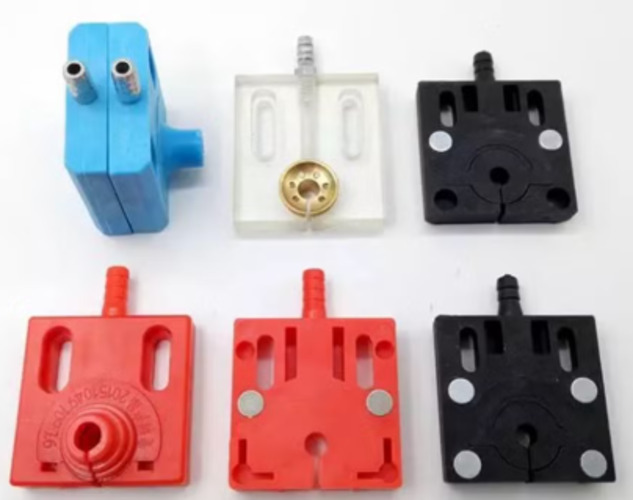

Edm water nozzle

Price 1400 INR/ Number

Edm water nozzle Specification

- Temperature

- Up to 80C

- Connector Type

- Push fit / screw mount (varies)

- Product Type

- EDM Water Nozzle

- Material

- Plastic, Brass

- Function

- Directs and controls the flow of deionized water to the electrode during EDM machining

- Usage

- Used in CNC EDM machine and wire cut EDM machine for efficient water flow and cooling

- Length

- Approximately 45mm (varies with model)

- Size

- Outer diameter: 10mm, Inner diameter: 6mm (subject to model)

- Color

- White/Transparent

- Diameter

- 6mm - 10mm

- Application

- EDM water flushing in wire cut and die sinking EDM machines

- Reusability

- Reusable and easy to clean

- Installation

- Simple plug and play or screw fit, depending on machine model

- Flow Pattern

- Straight / Narrow jet

- Water Pressure Compatibility

- Suitable for high and low pressure EDM cooling systems

- Corrosion Resistance

- High

- Maintenance

- Minimal, rinse with clean water after use

- Packing Type

- Polybag or bulk as required

- Compatible Machines

- Wire cut EDM, CNC EDM, Die Sinking EDM

Edm water nozzle Trade Information

- Minimum Order Quantity

- 1 Number

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 50 Per Day

- Delivery Time

- 1 Days

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Domestic Market

- All India

About Edm water nozzle

EDM (Electrical Discharge Machining) wire-cut water nozzles are specialized components used to optimize the cooling and flushing process during the wire EDM cutting operation. The nozzles control the flow of dielectric fluid (typically deionized water or a water-based solution) around the cutting area, which is essential for cooling the workpiece, removing debris, and maintaining the precision of the cut. Hereis an in-depth look at EDM wire-cut water nozzles:

1. Material

- Common Materials: Water nozzles for wire EDM machines are generally made from materials that can withstand the harsh conditions of the cutting environment, including high flow rates, chemical exposure, and wear. Common materials include:

- Brass: A popular material due to its excellent corrosion resistance, durability, and good conductivity, though it's generally used for lower-voltage applications.

- Stainless Steel: Used for its corrosion resistance and durability in more demanding environments or high-precision applications.

- Plastic: Some nozzles are made from durable plastics like PTFE (Teflon), which are resistant to wear and can be less expensive, though they are more commonly used in lower wear environments.

2. Function

- Flushing Debris: The primary function of the water nozzle is to flush away debris and particles generated during the wire EDM process. The nozzle ensures that these particles do not obstruct the cutting process, which can affect accuracy and surface finish.

- Cooling: EDM operations generate significant heat at the cutting zone. Water nozzles help cool the area by directing a controlled stream of dielectric fluid to the cutting zone, maintaining optimal temperatures and preventing heat-related damage to the workpiece.

- Maintaining Cutting Precision: The flow of water helps to stabilize the cutting environment, preventing issues such as short circuits or inaccuracies caused by the accumulation of debris.

3. Design and Shape

- Conical or Circular Opening: Water nozzles typically have a conical or circular opening to ensure an even flow of dielectric fluid. This shape helps direct the fluid in a manner that improves cooling and flushing efficiency.

- Multiple Ports or Holes: Some water nozzles feature multiple exit ports or holes to disperse the fluid more evenly across the cutting zone, enhancing the overall cooling and cleaning effect.

- Adjustable Nozzles: In many high-performance wire EDM systems, the water nozzle may be adjustable. This allows for fine-tuning of fluid flow rates, which can be important in achieving the desired cutting performance and surface finish.

- Dual Flow Nozzles: Some nozzles are designed to allow for dual flow, where two different streams of water are directed at the cutting area from different angles. This can enhance debris removal and improve cooling efficiency.

4. Size and Compatibility

- Wire Diameter Compatibility: Water nozzles are often designed to work with specific wire diameters. A nozzle that fits a 0.1 mm wire might not be suitable for a 0.3 mm wire. Matching the nozzle to the wire ensures optimal fluid flow around the wire and the workpiece.

- Flow Rate Adjustments: The nozzle must also be compatible with the required flow rate of the dielectric fluid, which can vary depending on the size of the workpiece, the type of material being cut, and the desired cutting speed.

5. Performance and Efficiency

- Flushing Efficiency: The design of the water nozzle plays a critical role in the overall flushing efficiency. A well-designed nozzle ensures that the dielectric fluid flow is strong enough to remove the debris but not too forceful as to disturb the cutting process.

- Cooling Power: The nozzle must provide adequate cooling to the workpiece. An effective water nozzle design maintains the temperature within optimal limits, preventing overheating or thermal damage during the cutting process.

- Wear Resistance: Water nozzles, especially in high-precision or high-volume operations, must resist wear over time. Continuous exposure to high-pressure water and abrasive particles can erode the nozzle, reducing its effectiveness.

6. Maintenance and Lifespan

- Clogging: Over time, nozzles can become clogged with debris, reducing the effectiveness of the flushing process. Regular cleaning is necessary to maintain proper performance.

- Wear and Tear: Water nozzles can wear out due to constant exposure to water flow and high-pressure environments. The nozzle opening may become wider or uneven, which can impact the flow of water and the precision of the cut.

- Replacement: Nozzles may need to be replaced periodically depending on usage, material being cut, and how effectively they are maintained.

Versatile Compatibility

This EDM water nozzle is compatible with a wide range of machines, including wire cut EDM, CNC EDM, and die sinking EDM equipment. Its design enables seamless integration, whether your setup requires a straightforward plug-and-play connector or a screw fit option. The nozzle supports an outer diameter range of 10mm and an inner diameter of 6mm, accommodating various models and operational requirements.

Efficient Cooling and Flow Control

Engineered to direct and control deionized water precisely to the electrode, the EDM water nozzle promotes optimal cooling and effective debris flushing during machining. Its straight or narrow jet flow pattern ensures that water reaches critical areas, maintaining performance even under high or low pressure conditions. The nozzle can withstand temperatures up to 80C, delivering consistent reliability throughout extended use.

Low Maintenance and Reusability

The nozzle's robust materials, including corrosion-resistant plastic and brass, guarantee long-term performance. Maintenance is minimal-simply rinse with clean water after use, ensuring the nozzle is ready for its next application. Its reusability and easy-to-clean construction make it a cost-effective addition to any EDM operation, minimizing downtime and upkeep demands.

FAQ's of Edm water nozzle:

Q: How is the EDM water nozzle installed on compatible machines?

A: Installation varies depending on the machine model-simply use the plug-and-play connector or screw fit option provided. Both methods facilitate quick setup and secure attachment to wire cut, CNC, or die sinking EDM machines.Q: What are the main benefits of using this EDM water nozzle during machining?

A: The nozzle delivers precise coolant flow for efficient electrode cooling, supports both high and low pressure systems, and helps flush debris away. Its corrosion-resistant materials and reusability reduce maintenance costs and improve operational reliability.Q: When should the EDM water nozzle be cleaned or maintained?

A: The nozzle requires minimal maintenance and should be rinsed with clean water after each use. Regular cleaning helps maintain optimal flow and prevents clogging, ensuring consistent performance over time.Q: Where can this nozzle be applied within EDM processes?

A: This nozzle is suitable for EDM water flushing applications in wire cut EDM and die sinking EDM machines. It is widely used across industries that rely on precise machining and effective cooling, such as manufacturing, fabrication, and metalworking.Q: What is the process for controlling water flow with this nozzle?

A: The EDM water nozzle directs a straight or narrow jet of deionized water, which can be adjusted for high or low pressure, depending on system requirements. This ensures targeted cooling and effective removal of machining debris.Q: What usage options do the nozzle's connectors provide?

A: The nozzle features push-fit or screw mount connectors, enabling flexible and secure mounting based on machine compatibility. This design ensures hassle-free installation and easy replacement whenever needed.Q: What are the benefits to dealers, distributors, and service providers in sourcing this nozzle from China?

A: Dealers and distributors benefit from the nozzle's high quality, versatility, and competitive pricing. Its adaptability to various EDM machine models, reliable performance, and bulk or polybag packaging options simplify logistics and inventory management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Molybdenum wires 0.18mm Category

JDC EDM Molybdenum Wire

Price 2,500 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Molybdenum

Function : suited for slicing, cutting

Color : Green

Product Type : JDC EDM Molybdenum Wire

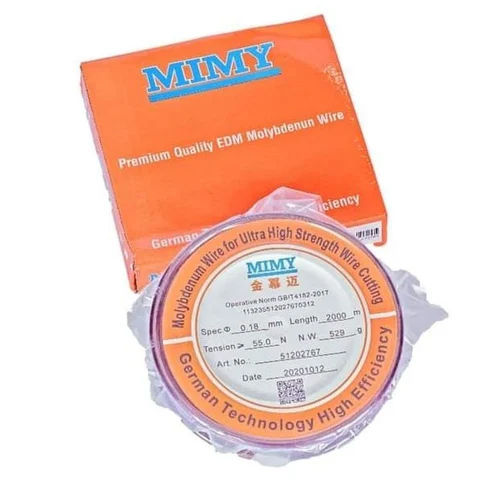

Mimy Premium Quality EDM Molybdenum Wire

Price 4,100 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Molybdenum

Function : suited for slicing, cutting

Color : Red

Product Type : Mimy Premium Quality EDM Molybdenum Wire

Black Diamond EDM Moly Wire

Price 4,200 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Molybdenum

Function : suited for slicing, cutting

Color : Black

Product Type : Black Diamond EDM Moly Wire

MIMY Molybdenum Wire

Price 4,000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Molybdenum

Function : suited for slicing, cutting

Color : Red/Black

Product Type : MIMY Molybdenum Wire

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese