Price 8000 आईएनआर/ Container

Specification

- उपयोग करें

- Automobile

- एप्लीकेशन

- Automotive

- टाइप करें

- Lubricant

- तेल का प्रकार

- Coolant Oil

- पैक टाइप

- Various Pack Size Available

Trade Information

- Minimum Order Quantity

- 1 Container

- भुगतान की शर्तें

- ,

- डिलीवरी का समय

- दिन

- मुख्य निर्यात बाजार

- , , , , , , , ,

- मुख्य घरेलू बाज़ार

- , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , ,

About

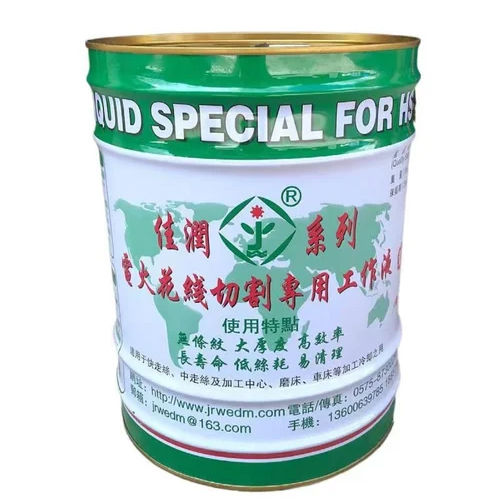

EDM (Electrical Discharge Machining) coolant, also known as dielectric fluid, is a specialized fluid used in EDM processes. EDM is a precision machining technique that uses electrical discharges (sparks) to erode material from a workpiece. The EDM coolant plays a vital role in ensuring the efficiency, accuracy, and safety of this process.

Functions of EDM Coolant:

Cooling: The EDM process generates a significant amount of heat due to the electrical discharges. The coolant helps dissipate this heat, preventing overheating of the workpiece and the electrode, which could otherwise lead to thermal damage and reduced machining accuracy.

Flushing: During EDM, tiny particles of material, known as debris or swarf, are eroded from the workpiece. The coolant flushes away these particles from the machining area, ensuring a clean and uninterrupted process.

Insulation: The coolant acts as an electrical insulator between the electrode and the workpiece. This insulation is crucial for maintaining controlled and precise electrical discharges, which are necessary for accurate machining.

Stability: The coolant provides a stable environment that reduces the risk of oxidation and corrosion, ensuring the longevity of both the workpiece and the electrode.

Characteristics of EDM Coolants:

High Dielectric Strength: Ensures that electrical discharges occur only at the desired points, improving precision.

Low Viscosity: Allows for easy flow and efficient flushing of debris.

Thermal Stability: Resists breakdown under high temperatures, maintaining consistent performance.

Non-Toxic and Environmentally Friendly: Designed to be safe for operators and less harmful to the environment.

Long Service Life: Stable chemical properties contribute to extended use without frequent replacement.

Common Applications:

Die-Sinking EDM: Used for creating complex shapes in hard materials like tungsten carbide, titanium, and Inconel.

Wire EDM: Employed for cutting intricate shapes and contours in conductive materials.

Precision Component Manufacturing: Widely used in industries such as aerospace, automotive, medical devices, and tool and die making.

FAQs:

Q1: How often should EDM coolant be replaced?

A: The frequency of replacement depends on usage, contamination levels, and machine specifications. Regular monitoring of the coolants condition is recommended, and it should be replaced when it becomes contaminated or its performance degrades, typically every few months.

Q2: Can EDM coolant be diluted with water?

A: EDM coolants are generally used in their concentrated form, and diluting them with water or other substances is not recommended. Dilution can alter the coolants dielectric properties, reducing its effectiveness and potentially damaging the EDM machine.

Q3: How should EDM coolant be stored?

A: EDM coolant should be stored in a cool, dry place, away from direct sunlight and contaminants. It should be kept in tightly sealed containers to prevent contamination and degradation.

Q4: Is EDM coolant hazardous to health?

A: Most EDM coolants are formulated to be non-toxic and safe for operators. However, its important to follow safety guidelines, including using protective gear and ensuring proper ventilation in the workspace. Always refer to the Material Safety Data Sheet (MSDS) for specific safety information.

Q5: How should used EDM coolant be disposed of?

A: Used EDM coolant should be disposed of in accordance with local environmental regulations. It should not be poured down drains or released into the environment. Many regions require disposal through certified waste management services.

Q6: What factors affect the performance of EDM coolant?

A: The performance of EDM coolant can be affected by factors such as contamination (with debris, oil, or other substances), degradation due to heat or chemical breakdown, and improper storage. Regular maintenance and monitoring are key to maintaining optimal performance.

FAQs of EDM COOLANT:

Q: What is the pack size available for EDM COOLANT?

A: The pack size available for EDM COOLANT is 800ml, 900ml, and 1L.Q: Is EDM COOLANT specifically designed for automobiles?

A: Yes, EDM COOLANT is designed for automotive use.Q: What type of oil is EDM COOLANT classified as?

A: EDM COOLANT is classified as Coolant Oil.Q: Can EDM COOLANT be used as a lubricant for automobiles?

A: Yes, EDM COOLANT can be used as a lubricant for automobiles.Q: What are the different pack types available for EDM COOLANT?

A: The pack types available for EDM COOLANT include various pack sizes.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

अधिक Products in ईडीएम कूलेंट जेल Category

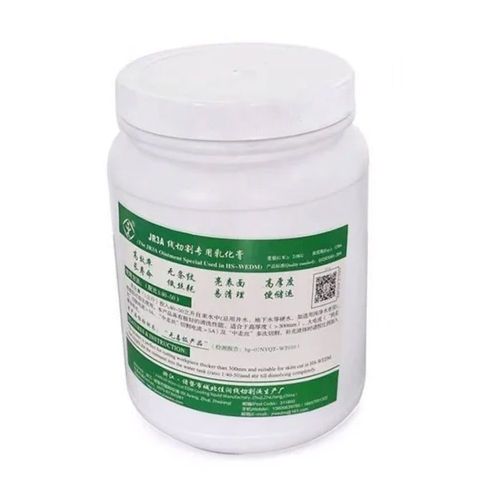

जियारुन जेआर 1 ए ईडीएम कूलेंट जेल

मूल्य की इकाई : लीटर/लीटर

माप की इकाई : लीटर/लीटर

मूल्य या मूल्य सीमा : आईएनआर

न्यूनतम आदेश मात्रा : 100

पैक टाइप : जे आईए रन जूनियर1ए ईडीएम कूलेंट जेल

उपयोग करें : औद्योगिक

जांच भेजें

जांच भेजें

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese